Discover how to take the next step in your organization’s evolution.

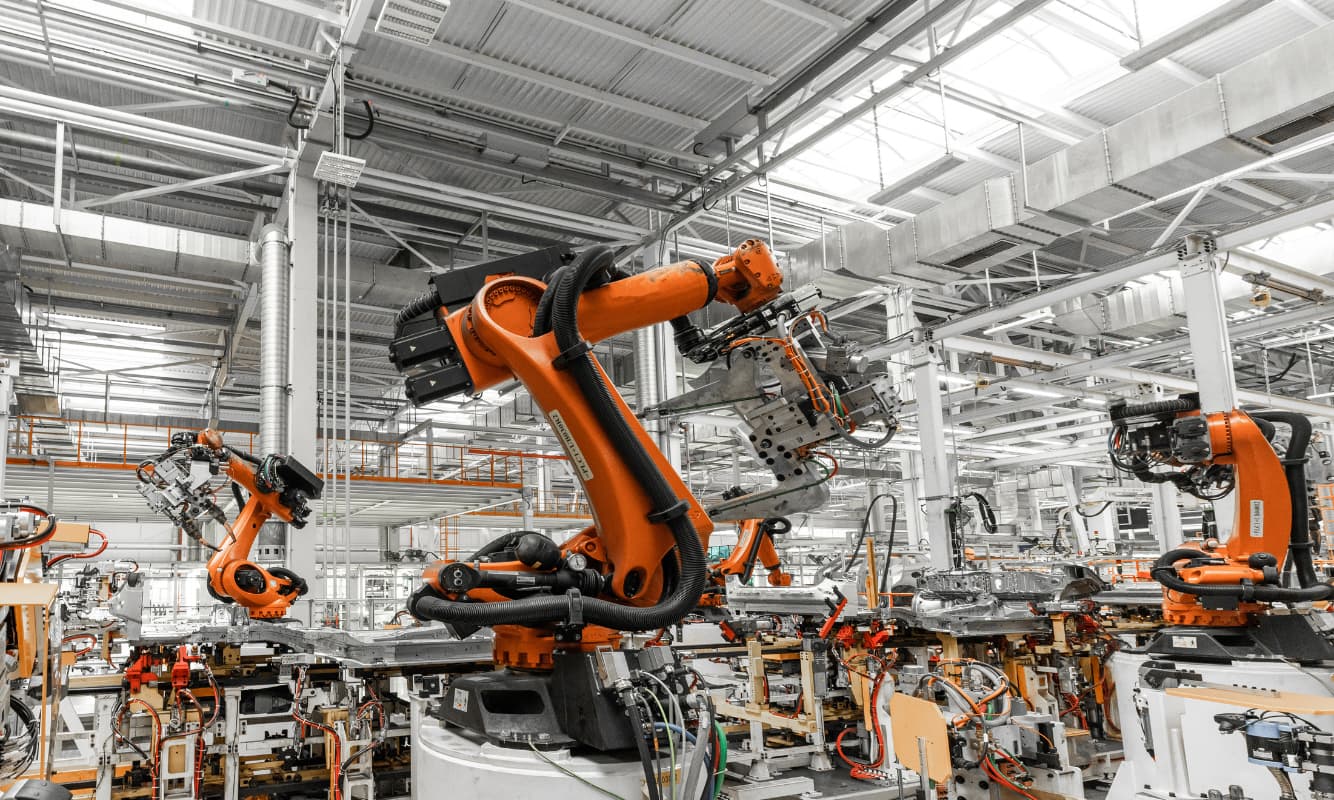

Digital transformation is ushering the manufacturing industry into a new era of efficiency, where speed, agility, and connectedness have become increasingly critical to survival. Technologies like artificial intelligence (AI), robotics, and the Internet of Things (IoT) are accelerating this evolution, driving efficiency and cost savings by enabling manufacturers to promptly deliver the correct information to employees within the context of their physical work environment.

From improved workforce productivity to increases in quality and yield, forward-thinking organizations are seeing the impact of adopting Industry 4.0 technologies across the value chain. Not embracing this revolution means you risk falling behind and missing all the opportunities.

This article examines manufacturers’ key challenges in achieving efficiency and how digital transformation can address them. Ready to explore? Let’s dive right in!

Key Challenges to Manufacturing Efficiency

Efficiency remains a critical determinant of industrial competitiveness. Yet many organizations are lagging in this department. Where is the problem?

For many, outdated systems are what’s slowing down production and operation. For example, legacy control systems lack the computational capacity to process real-time data from IoT devices. This means manufacturers can’t make fast decisions on the factory floor. Further, these obsolete systems lack fundamental compatibility with modern digital tools and automation solutions, so relying on them means operating in a fragmented technology environment.

Another issue with traditional manufacturing is that it involves extensive manual processes, which introduce statistically significant quality risks across manufacturing verticals. As you know, errors create multiplicative rework, leading to production delays. Plus, manual processes have limited scalability. As production demands increase, scaling them can be an uphill task.

Digital transformation can help overcome these challenges.

How Digital Transformation Reshapes Manufacturing

Automating Production Lines

A key digital transformation objective is to enhance output. Looking specifically at shop floor operations, technologies like robotics, IoT, and AI facilitate next-generation automation. Smart robots embedded with AI and connected via industrial IoT platforms analyze available data and make autonomous decisions about the best next actions to be taken at the assembly line. All this happens in real-time, with help from edge computing and analytics capabilities. In addition to acting autonomously, these intelligent robots can collaborate with humans to improve efficiency across the board.

Data-Driven Decision-Making

With digital transformation, you can harness predictive insights from data to improve daily operations. For example, you can analyze whether processes are efficient enough, examine how to improve quality, and determine the metrics driving quality. When you can take your data and determine what will happen next, you can trigger operations to be more efficient ahead of the game. That could be for a specific production line, a whole plant, or even the entire enterprise. Ultimately, this data-driven decision-making helps you reach the point where you reduce waste and improve quality.

Cloud-Based Solutions

With cloud computing at the core, manufacturers can consolidate data from all their sources—whether their enterprise resource planning (ERP) systems or IoT platforms—for comprehensive real-time analytics and decision-making. The cloud’s flexibility to scale capabilities on demand makes managing fluctuating production cycles and global supply chain challenges easier.

Improved Collaboration

Using digital communication tools breaks down traditional silos between engineering, production, and quality control departments. This means that teams can quickly share insights, align on strategy, and accelerate problem-solving.

Why Embrace Digital Transformation in Manufacturing?

Digital transformation can significantly impact your organization from a manufacturing standpoint. You collect a tremendous amount of data: process data, quality data, and performance data. With modern technologies, you can turn that raw data into insights and put it at the fingertips of people who need it to make correct decisions. This can improve operational efficiency, enhance product quality, and reduce production costs.

An accurate end-to-end view of your value chain is critical to understanding where inefficiencies lie. Digital and Industry 4.0 technologies allow you to focus on your bottlenecks and constraints and remove them in ways you wouldn’t otherwise be able to. So, by adopting them, you boost productivity and build resiliency. You reach new agility, flexibility, and adaptability levels, which you will need to face future disruptions.

NRI’s Approach to Digital Transformation

As part of your digital transformation, you will invest significant money in different technologies that will likely define your business and strategy for the next 10 years. Why wouldn’t you also invest a small amount to ensure these investments are done correctly? This is where digital transformation consulting comes in.

NRI is here to help you identify how to invest for success. All the exciting manufacturing technologies—AI, IoT, robotics, big data, analytics, and more—cannot be implemented simultaneously. Some even won’t be the perfect fit. Plus, there’s no one-size-fits-all approach to digital transformation. Solutions must be specific to your business pain points and digital maturity.

Over the years, we have developed a comprehensive methodology to tailor digital solutions for different manufacturing operation needs. This has been proven with many customers, including one that extensively integrated its systems for efficiency and successfully eliminated $200,000 in legacy support and maintenance fees.

It’s about asking these valuable questions:

- Why are you spending money on digital transformation? Is it to reduce the time to market, increase productivity, ensure better product quality, or something else?

- Where do you stand today? Are you already using AI and other Industry 4.0 technologies? How is your automation at work performing? Is your data connected or operating in silos?

- What are the best solutions? Do you really need to invest in new technologies, or can your toolkit optimize existing solutions to meet needs?

- What must be prioritized? You will discover many pain points and opportunities. The problem is that you cannot solve them all in one go. So, you need to prioritize.

- What investments do you need? Here, we deep dive into the projects you’ve prioritized and calculate the investment you need and the ROI to expect based on your specific case.

Answers will provide a complete view of where you stand, what systems exist, and the landscape of your system’s future. They will help identify the missing pieces to invest in, costs, and ROI. Once you have this clarity, we can discuss how NRI will support you with a custom solution implementation.

Want to learn more? Take the next step of your digital transformation journey by scheduling a free one-hour consultation with our experts.