Unlock the value of connected operations without compromises.

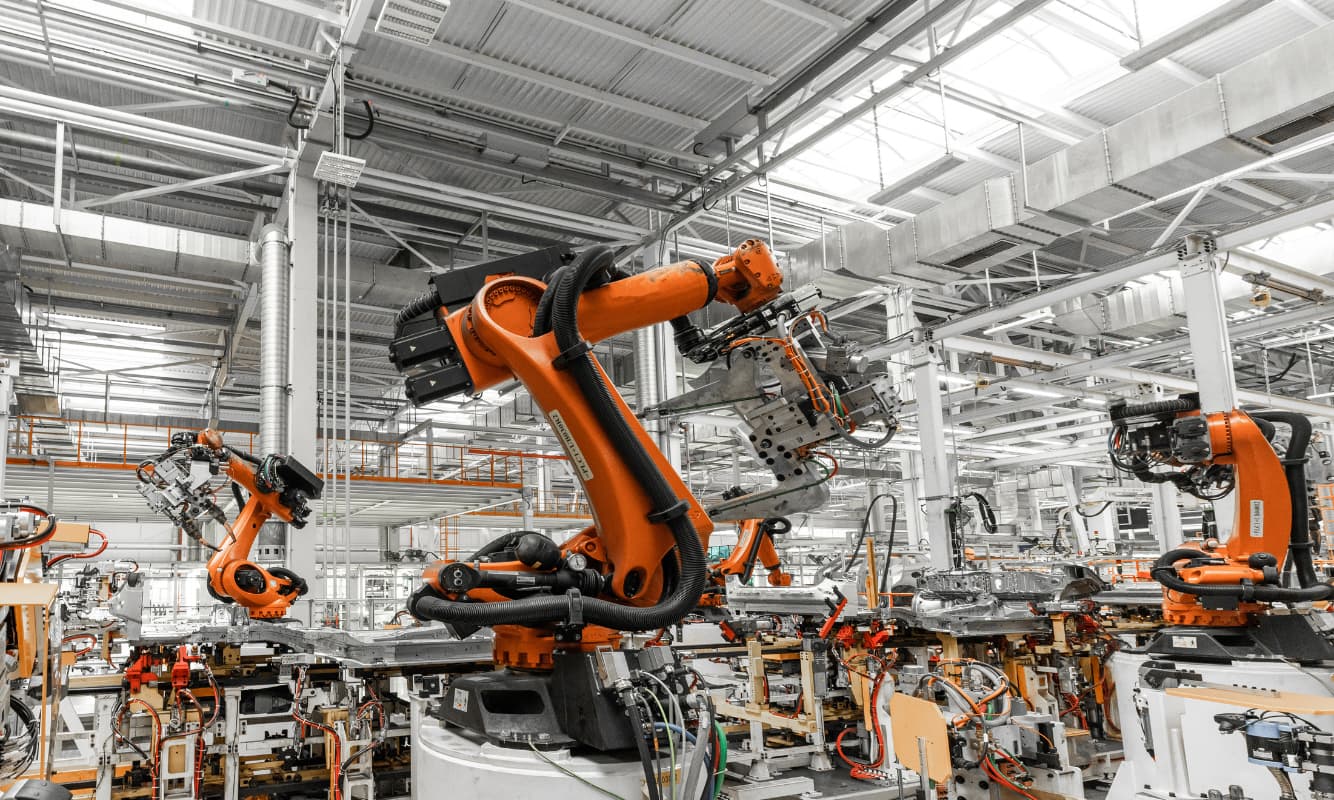

The Industrial Internet of Things (IIoT) has become the driving force behind modern manufacturing. Sensors, autonomous robots, cloud gateways, and other connected devices now choreograph every production process, from raw material intake to predictive maintenance decisions, allowing factories to run faster, leaner, and smarter. Yet with every new IP address introduced into the shop floor, the blast radius for cyber-attackers widens. For leaders making technology decisions, the question has moved from “What should we connect?” to “How can we stay secure while we connect?” And rightly so, as information technology (IT) and operational technology (OT) become increasingly intertwined, a single compromise could halt production, trigger a safety event, and result in financial losses of up to $5.56 million, according to IBM. Fortunately, proven strategies can help you stay ahead of the cybersecurity curve. Here’s everything you should know.

The Expanding Threat Landscape in IIoT

Today, many forward-thinking manufacturers have collapsed the air gap between IT and OT networks to feed real-time analytics platforms and unlock more value from their smart factories. This has inadvertently expanded the attack surface and introduced new cyber risks.

One emerging theme is the increasing threat of ransomware targeting supervisory control and data acquisition (SCADA) systems. IBM reports that ransomware attacks doubled in 2022, while additional statistics from Dragos indicate a subsequent 60% increase between 2023 and 2024, plus another 87% jump last year.

These attacks compromise data integrity and pose safety hazards and operational disruptions. A notable example is the RansomHub group breach of the Spanish bioenergy plant Matadero de Gijón’s SCADA systems. RansomHub claims to have encrypted and exfiltrated over 400 GB of data, including operational and possibly proprietary information. They also demonstrated they could remotely control the biogas facility’s digester and heating systems.

Another common theme is artificial intelligence (AI)-powered phishing campaigns targeting OT environments. Threat actors now leverage sophisticated data analysis of malicious AI toolkits, such as WormGPT, to gather detailed information about a target’s role, projects, and digital footprint from sources like LinkedIn and breached email logs and craft highly convincing emails. For instance, an attacker might send a personalized email impersonating a known vendor or internal engineer, requesting urgent credentials or a malware installation in the guise of a “software update” for SCADA or industrial control system (ICS) components. For OT personnel who are seldom security specialists, these spoofed requests can be hard to spot.

NRI supports leading manufacturers with risk assessments that inventory every asset across IT and OT environments, map exploitable pathways, and rank remediation by operational impact, ensuring security spending targets areas that remove the most risk. Learn more.

The Challenges of Securing Industrial Systems

Manufacturers face unique challenges in securing industrial systems. First, and most notably, is the issue of legacy equipment. For example, many programmable logic controllers (PLCs) were installed long before cybersecurity was a design requirement. While they may be reliable and functional, they often lack authentication, encryption, patch support, and other controls to fend off modern threats.

The real-time operational demands of modern manufacturing make downtime for updates or audits unacceptable, further complicating the security equation. For example, shutting down a production line that runs at 150,000 units per hour to apply a firmware patch could severely disrupt production. Yet, patching delays leave known vulnerabilities exposed.

Additionally, today’s complex environments easily create blind spots and unmanaged endpoints. Maintaining visibility and control over thousands of connected devices, which may utilize multiple protocols and communication channels, is challenging. Yet, it’s non-negotiable. Implementing consistent security and governance policies across the IIoT ecosystem requires a complete inventory of your connected assets.

NRI designs customized IIoT security architectures that address legacy tech constraints while maintaining operational continuity. Learn more.

Modern Cyber Defense Strategies for IIoT

Securing IIoT-powered environments requires modern defense strategies, starting with Zero Trust. As the convergence of IT and OT creates complex boundaries, no device or user should be trusted by default. All network communications should be continuously monitored and verified. Your Zero Trust strategy should include robust network segmentation to limit the spread of potential security incidents. Leverage advanced techniques like micro-segmentation to create granular security zones for effective threat containment while maintaining necessary operational communications.

Additionally, anomaly detection and behavioral analytics should be implemented to rapidly catch bespoke OT malware and threats that typically evade traditional signature-based security tools.

Lastly, with firmware vulnerabilities representing a particularly insidious threat vector, organizations must implement a formal firmware management program for existing and incoming assets. Device security throughout the entire lifecycle requires implementing secure onboarding processes, enforcing firmware integrity verification, and protecting remote access capabilities.

NRI integrates advanced threat detection and monitoring into IIoT networks using industry-compliant tools aligned with ISA/IEC 62443 and NIST standards. Learn more.

Building Operational Resilience with Proactive Security

True operational resilience requires developing comprehensive incident response capabilities designed for OT environments. Your OT-focused plan must consider the physical safety implications of security incidents, prioritize critical operations, and include predefined procedures for isolating compromised systems while maintaining essential production capabilities.

According to Verizon’s 2025 Data Breach Investigations Report (DBIR), the human element now accounts for 60% of compromises. Training OT staff to recognize and respond effectively to digital threats will be crucial in fortifying your first line of defense, reducing human errors, and fostering a security-first culture.

Lastly, business continuity planning for IIoT environments must incorporate cyber contingencies alongside traditional operational risks. These plans should address scenarios ranging from targeted ransomware attacks to widespread network compromises, ensuring organizations can maintain critical operations even under adverse conditions.

NRI’s 24/7 Managed Security Services (MSS) offer real-time threat hunting, incident response, and SOC support tailored to industrial environments. Learn more.

The Future of Secure Smart Manufacturing

As Industry 4.0 evolves, protecting data flows, edge devices, and AI models will be critical. All manufacturing IT leaders and decision makers must be proactive and bake security into every aspect of their digital transformation initiatives for meaningful and lasting innovation. Ultimately, this is the best path to enabling remote operations, predictive maintenance, and optimized output, as well as fostering trust with partners and regulators.

NRI helps leading manufacturers scale their digital transformation securely and seamlessly.

We provide:

- Strategic consulting to align security with your business objectives

- Hands-on technical implementation of all appropriate controls

- Change management support for your workforce

- Ongoing support and monitoring post-implementation

We help you protect what you have today and build security into the blueprint of what you plan for tomorrow, whether deploying a new fleet of IoT sensors across your plants or integrating AI into your quality control process. The result is a future-ready, cyber-resilient operation. Schedule a custom consultation to learn how much more secure your organization can be with NRI.