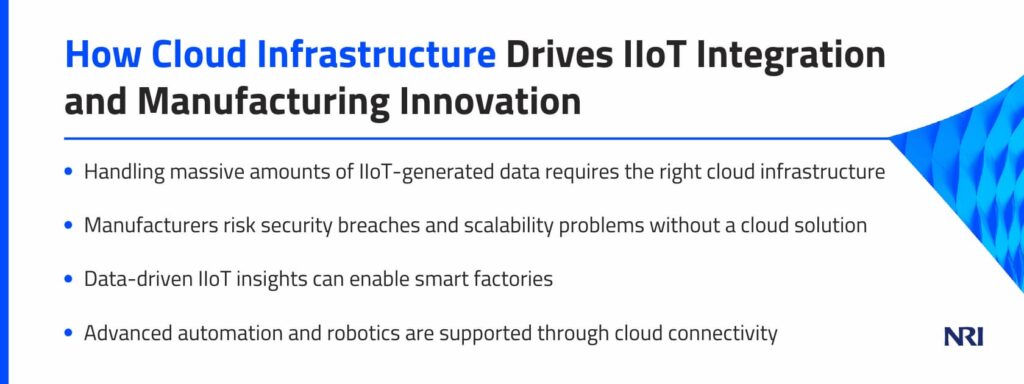

To fully realize the benefits of IIoT integration, manufacturers need a sound infrastructure to handle the data load.

New technologies are reshaping manufacturing operations, driving the shift into the fourth industrial age, or Industry 4.0. Powered by the Industrial Internet of Things (IIoT), this transformation enables “smart” factories with advanced connectivity and data capabilities. These innovations improve efficiency, predict maintenance needs, track assets, and enhance customer service.

However, for these technologies to work at their best, they require a cloud structure that drives IIoT integration and manufacturing innovation.

What Is the Industrial Internet of Things?

The IIoT can be described as “the use of smart sensors, actuators, and other devices, such as radio frequency identification tags, to enhance manufacturing and industrial processes. These devices are networked together to provide data collection, exchange and analysis. Insights gained from this process aid in more efficiency and reliability. Also known as the industrial internet, IIoT is used in many industries, including manufacturing, energy management, utilities, oil and gas.”

The smart machines and real-time analytics to identify problems earlier, optimize processes, provide better quality control, manage supply changes more efficiently, and much more.

IIoT is a cornerstone of Industry 4.0, which also uses cloud computing, analytics, AI (artificial intelligence), and machine learning to create smart manufacturing processes. Large amounts of data collected from factory floor sensors help reduce manufacturing errors and save time and money.

Challenges in IIoT Integration Without Cloud Infrastructure

The challenge with smart manufacturing is that it becomes less intelligent if it doesn’t have a strong cloud infrastructure to handle the massive amounts of IIoT data it generates. The cloud makes true connectivity possible by integrating engineering, supply chain, production, sales and distribution, and service.

Its capabilities enable manufacturers to process and analyze vast amounts of data far more efficiently and cost-effectively than in a non-cloud environment.

A lack of centralized systems for real-time monitoring and analytics can pose security risks and limit scalability.

How Cloud Infrastructure Supports IIoT Integration

A strong cloud structure can enhance your system security, protecting IIot networks and sensitive manufacturing data. Of course, traditional manufacturing processes didn’t pose many security risks, but the sensor-connected machines of smart factories open businesses to the attacks of bad actors.

So, a comprehensive cloud solution must cover both IT and OT (operational technology) with its cybersecurity blanket, which might include multifactor authentication, end-to-end encryption, and setting up custom authorization levels.

An IIoT solution may need to support many connected machines and scale up and down to meet rising and diminishing demands. This kind of flexibility is built into the best cloud infrastructures.

The cloud also enables global accessibility, allowing teams to monitor and control operations remotely. It also helps the smart machines at the heart of Industry 4.0 communicate, producing intelligence that yields actionable insights to enable predictive maintenance, optimize processes, and improve business decision-making.

Key Innovations Cloud Brings to Manufacturing

Cloud connectivity offers several important benefits to manufacturers embracing smart factories. For example, it supports advanced automation and robotics, using M2M (machine-to-machine) communication for efficiency.

Robotic sensors might alert manufacturers to predict and prevent machine failures, which can cause expensive downtime. The real-time information that is produced in a cloud-support manufacturing operation can be used to drive business decisions, perhaps enabling companies to break down information silos so they can share data with ERP (enterprise resource planning), supply chain, customer service, and other enterprise systems to enable greater visibility into processes and provide the basis for more decisive strategic decision-making.

Cloud-based IIoT technologies can also help field service technicians identify issues in customer systems before they become problems. They can get specific information on the parts needed to make a repair so they can be properly armed before they leave the office on a service call.

Asset-management systems enable manufacturers to track the condition of parts or machinery throughout their supply chain, providing alerts if the goods are damaged or at risk of becoming so.

Not only can IIoT technologies provide predictive maintenance for machines, ensuring production lines don’t have unnecessary and costly stoppages, but their sensors can also be used to monitor vibrations, temperatures, and other conditions that can lead to subpar machine performance.

Cloud-based IIoT can also help to:

- Accelerate innovation

- Create an end-to-end visibility of operations

- Reduce operating costs

- Optimize production scheduling

- Boost overall equipment effectiveness

NRI’s Role in Manufacturing Transformation

If you are looking for a cloud solution that drives IIoT integration for your business, look no further than NRI. We are experts in creating cloud infrastructures that are the foundation for truly successful smart manufacturing.

We keep our finger on the pulse of global manufacturing trends and technologies and have deep experience in helping manufacturers like yourself to future-proof their businesses. We can help you leverage advancements in automation, AI, predictive analytics, and other technologies to design solutions that optimize production lines, streamline processes, and boost productivity.

Whether your concern is remote monitoring of manufacturing operations, quality control, predictive maintenance, worker safety, inventory management, supply chain efficiency, or something else, we can find the right cloud infrastructure to fill your needs.

Contact us today to get a smart cloud solution for your smart manufacturing business.